| |

|

|

Benefits

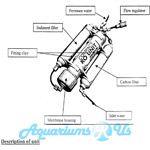

of using RO water Water companies have a responsibility to supply water which is of "potable" quality, this means that it must be of a safe and drinkable quality. This however does not mean that it is safe or suitable for the use of fishkeeping. In fact the addition of chlorine or chloramines to our drinking water by the water companies can make it positively lethal to our fish in some cases. Water is probably the greatest solvent known to man. As water passes through the hydrological cycle it can accumulate many undesirable qualities and pollutants, amongst these the most commonly know are Nitrates, Phosphates, Heavy metals and water hardness; all of which can be detrimental to the fish and systems we try to maintain. RO systems can remove up to 99 % of these contaminates. All types of fish and aquatic systems benefit from the use of RO water. Not only soft water and delicate species such as Discus, through the reduction of water hardness, Marine fish and inverts through the reduction of Nitrates and heavy metals, but all systems throught the reduction of Phosphate and Nitrate levels, the single biggest causes of nuisance algae in any aquatic system. Within an RO unit there is a very tighly bound semi permeable membrane. By applying osmotic pressure in the form of tapwater mains pressure (min 3bar) to one side of this membrane pure water molecules are forced through, leaving the larger molecules such as nitrates and phosphates behind. This results in a very pure (max 99%) source of soft water and a more concentrated waste water. RO water can in fact be too pure for the purpose of fishkeeping, as all natural salts are removed; thererfore it is important to recondition the water using a propriety treatment. Please ask your supplier for advice and details of conditioning treatments available. BASIC OPERATING CONSIDERATIONS Ouput capacity varies according to room temperatures and water pressure. Higher temperature and pressure result in higher performance. RO units are not to be operated under extreme conditions of temperature or pressure. Permeate flow rate is based on standard test conditions and may vary depending on feed water quality. Individual elements permeate low may vary up to 15%. Elements in the units contain preservative solution, therefore the permeate from the first hour of operation should be discarded. A sediment pre-filter and an activated carbon filter are fitted as standard. This means the unit maybe used irrespective of sediment and chlorine content of the untreated water provided it conforms to European drinking water standards. The water should always flow through the activated carbon filter before the sediment pre-filter. This prevents any dusts from the carbon which may shake loose during transport reaching the membrane and reducing performance. Water from the waste pipe should connected to a waste water system or alternatively this concentrated waste can be collected and used for other purposes but MUST NOT BE CONSUMED. Shutting down the unit To simply stop production, turn off feed supply, however the membrane MUST NOT be allowed to dry out. If unit is off for more than 7 days, allow the unit to run to waste for 30 miuntes before collecting permeate water. If the unit is to be shut down for longer eriods we strongly advise the installation of 2 isolation valves. One connected to the waste piepl and one connected to the permeate pipe. This will help stop the ingress of bacteria into the unit and also ensure that the unit remains full of water nad stop the membrane from drying out. The unit should be flushed for a minimum of 2 hours when reinstated. The sediment and carbon prefilters require changing every 6-12 months depending on the quality of supply water. A significant reduction in flow indicates a blocked prefilter. Depending on the quality of supply water the TFC membrane may need to be replaced every 2 to 8 years provided the prefilters have been regularly changed.

|

|